No action onsite this week, and this blog post almost didn’t get written as I didn’t think there was enough to talk about. However, Kristian came to the rescue Thursday night with a truss design issue that has given me some content. We had also just about finalized the selection of our plumbing fixtures, and have been refining our joinery, so between sets at the gym Friday morning was spent typing this in my notes. Turns out I can waffle on once I get going….

Our trusses are being made by The Truss Joint in Bendigo and we often work with them on our projects, particularly on anything a little bit out of the ordinary. Bruce Wallace is passionate about trusses and timber and loves finding solutions to complex design problems. Early advice suggested the trusses would work fine; however, he was having some difficulty when it came to work them out properly. One solution was to increase the pitch from 8 degrees to 9, and Kristian called to run that by me on Thursday night.

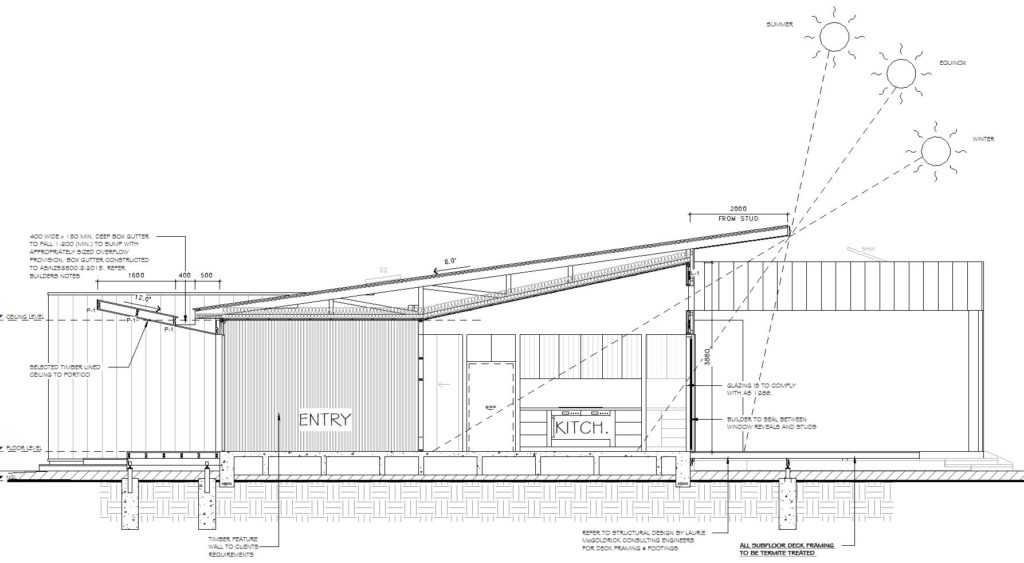

I had designed the roof with an 8-degree pitch and had optimized the appearance and shading based on this. Therefore, it was back to the drawing board (computer) Friday morning to see how the 9-degree pitch would look and what affect it would have on the shading. At work we use 3D CAD software (REVIT) that allows us to model the sun shading at any location at any time on any day throughout the year. This is a valuable design tool and an excellent way to demonstrate how solar passive design can work.

I found the appearance still looked right at 9 degrees, however, was not comfortable with the additional exposure caused by the increased pitch and eave height on the north. Shading for north facing windows in peak summer is easy as the sun is high, and it is surprising how little eave width you need. Where it gets tricky in our climate is in late summer, late February and early March, were the sun is lower, but we still get really hot days. The eave needs to be quite wide at this time of year, however the wider it is the more winter sun it will block. I had the balance just right, so if we were going to make the eave higher it would need to be wider.

I got on the blower to Bruce and he ruled out a wider eave as 2m was at the limit of what he could do without requiring an oversized fascia. I did some research on this and it was going to add significant expense, so we needed to stick to a standard fascia depth. We discussed the roof design over the garage which was causing the problem and were able to find a solution to retain the 8-degree pitch. Just in time as they almost started making them!

During the week we nailed 95% of our plumbing fixture selections. Still can’t find the right kitchen and pantry sink mixer, so have decided to leave them out for now. We are going with matte black tapware and fixtures, see the main selections below:

I will give more detail once we order or install, hopefully I can get a discount for the promotion!

We have also almost finalised our joinery. Main items include:

- Stone kitchen bench top with timber slats below.

- Soft close kitchen drawers

- Vinyl panel overhead cupboard doors

- Timber desktops, likely messmate

- Timber daybed and drop zone, likely messmate with vinyl panel drawers

- Stone powder room vanity with timber slats below.

We have cleared a bay in our shed ready for materials and filled a fridge full of great northern cans to entice the builder. All set to go, ready for the framing stage👍

2 thoughts on “Blog #7: Truss design, shading, plumbing fixtures.”

Was the problem the shed blocking the winter sun?

Hi Dennis, no the shed is positioned far away enough not to block any winter sun.