The build seems to be moving rapidly and we have been pleased with the progress. A lot happened early in the week, but rain slowed things up towards the end of the week. A little annoying, but one should not complain about rain in these parts!

The rest of the house trusses went up on Monday and the boys spent the next few days bracing and tying them down. They have started battening and doing the end overhangs, although the 2m north eave is providing some headaches.

There is still the portico, alfresco, and East end eave overhang to frame up as these require some steel work and onsite framing. The steel has been fabricated by AB Building and will be powder coated this week at Maher’s Glassworks.

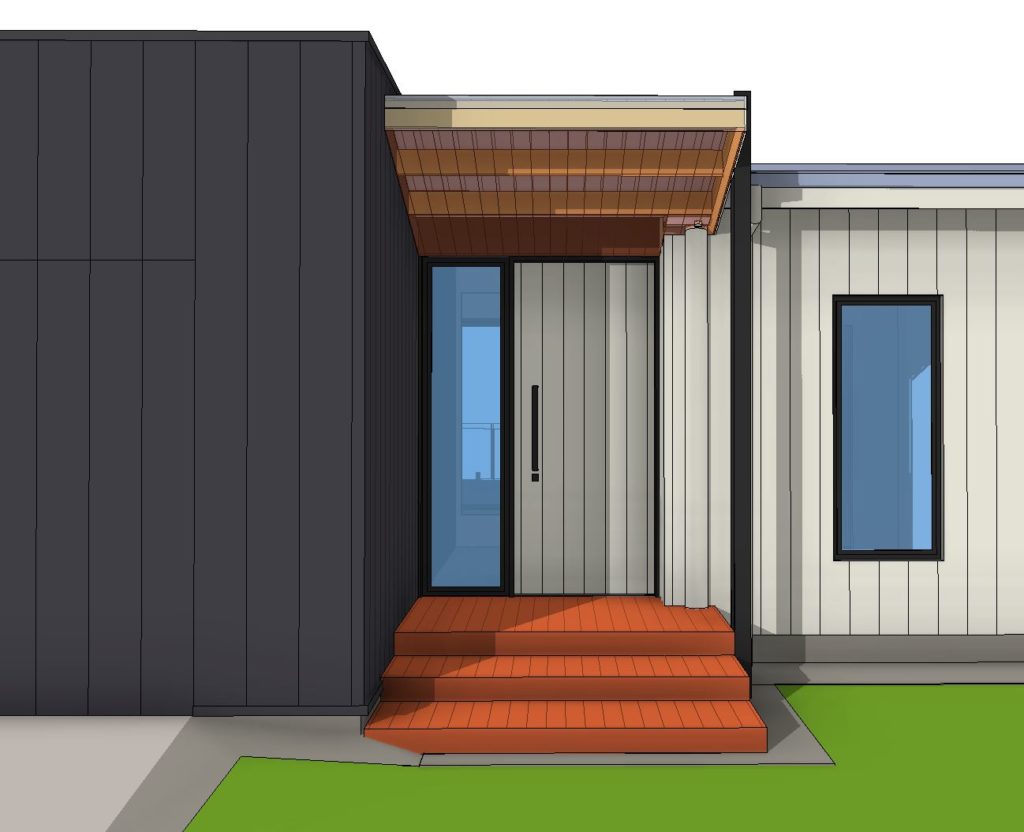

I assisted here by providing 3D drawings to avoid any confusion for the builder and the fabricator. Kristian seemed pleased with these and had me do the same for the portico roof. The luxury of building a house for a draftsman. The drawback is the 1000 sets of revised plans, which has caused a couple of hiccups.

Still a heap happening behind the scenes. A few ups and downs but I felt as though the pieces of the puzzle fell into place by the end of the week.

What I am finding is that anything non-standard takes lot more time and effort and hence more expense. My advice would be to pick your battles, as it is not worth the effort on items you are not fussed about. So, work out what you want, see if there are standard options, if not be sure you really want it, and be committed to invest time and money to make it happen. You will be met with some resistance but there is always a way.

One battle that I won this week was with our seamless garage door. I want this to be clad the same as the walls and was hoping to use Matt Monument/black colorbond in a standing seam type profile. Early research suggested this was doable if we were able to use battens rather than plywood backing, however I had underestimated the weight of the door frame. Turns out the frame will need to be 80-100kg which only leaves 75–95kg for the cladding, battens, and flashings.

I called Metal Cladding Systems (MCS) in Melbourne, who supply to Dahlsens, to discuss cladding options. They ruled out standing seam, as it requires a plywood backing, and recommended I use their ‘Nailstrip’ system, which looks similar to however is easier to install and can be fixed to battens. They provided a spreadsheet with the accurate weights of the whole system and we soon found that colorbond steel would be too heavy for my door size. I toyed with the idea of a smaller door, but it would have to be too small. I had previously considered 2 separate doors but thought this did not look as good. They suggested I could use aluminium which is lighter and can be folded into the same profile.

We did our research and found a colour we like and got some prices from Dahlsens. Naturally, it was more expensive, however we are committed to this design feature so think the investment will be worthwhile.

The rest of the house will also be metal clad in their “Interlocking” system, so this was also discussed with MCS. This is a new system to Kristian and me, so we had been working with Maher’s Glassworks on how to finish it around windows. MSC gave some great insight and has even offered to send one of their specialist installers next week to meet onsite to assist with set out, flashing options, and show us material samples. This will be a great help and will make the cladding install run a bit smoother.

One battle I lost was over retractable screen doors. Our door panels are 1.5m wide so too wide for good gal mesh screens which normally seem to be way to go. We have been researching our options, and I really liked the idea of retractable screens as they could be fully retracted when not in use, leaving the glass doors fully unobscured. These ideally needed to be considered earlier in the design process and provisions made in the wall framing. These were discussed at length however after reading online reviews and considering the costs we decided to abort. We have since found a suitable alternative, screen doors with stainless steel mesh, which come in 1.5m panels, look the same as gal mesh, however a bit more expensive. Last week i said that our budget was intact, this week I am not so confident….

Air conditioning was also a big topic for discussion this week. It started early in the week when we had to work out where to fit the indoor unit. We are having a ducted reverse cycle system which consists of an outdoor condenser unit and an indoor unit which is placed in the ceiling space with ducting going to each room. Our roof is only 8 degrees so it will be tricky to fit it all in. I met with Darren Berry from Berry Refrigeration onsite and discussed the system and he has since provided us a quote. We have a friend in Adelaide (g’day Matty) who works in Air Conditioning, so he has been assisting us in trying to work out what bells and whistles to include. There are some pretty cool options now a days, with Wi-Fi controls, individual room zoning, and sleek vents, so we will work out what is practical over the next week or so.

And that is where it sits ATM. We will be onsite tomorrow cleaning up while the kids play in the puddles in their jocks. We look forward to seeing more progress in the coming week. A roof will not be far away, which will be awesome.